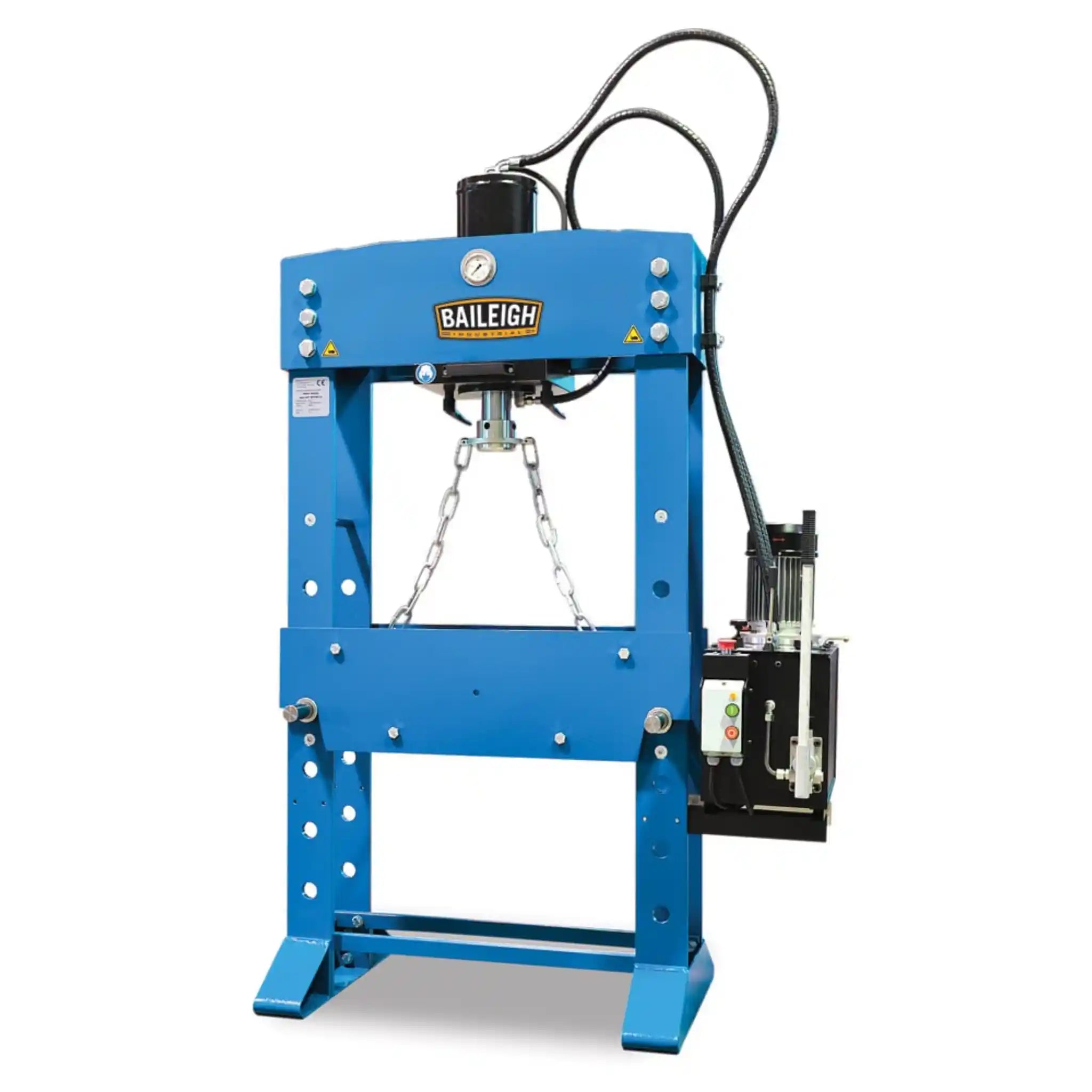

Baileigh HSP-66M Hydraulic Workshop Press

The Baileigh HSP-66M is a professional grade 60 ton hydraulic H-frame press that delivers industrial power and precision for your metalworking shop. Built in the Netherlands with premium European craftsmanship, this robust machine combines exceptional force capacity with intelligent dual speed operation to handle everything from delicate bearing work to heavy duty metal forming.

When you need serious pressing power that doesn't compromise on control, the HSP-66M is your answer. This isn't just another shop press. It's a carefully engineered piece of European metalworking equipment designed to withstand decades of hard use in demanding professional environments.

At the heart of this machine is a fully welded 3/8" plate steel frame that can handle every bit of the 60 tons of hydraulic force without flexing or compromising accuracy. You're looking at 685 kg of solid construction that stays put when you're working on challenging jobs. The industrial grade hydraulic system delivers consistent, reliable pressure through a robust 1.5 kW motor running on 400V three phase power.

What sets the HSP-66M apart is its intelligent approach to control. You get two automatic working speeds: a rapid descent mode that saves you time positioning your work, and a slow approach speed for precision pressing. Need even finer control? Switch to the included hand pump for those delicate operations where every millimeter matters. The movable cylinder design is another smart feature, it slides left or right within the frame so you can apply pressure exactly where you need it, even on off center workpieces.

This press is perfect for fabrication shops, machine shops, automotive repair facilities, and maintenance departments. Whether you're pressing bearings, straightening bent components, forming metal parts, or assembling tight fitting assemblies, the HSP-66M gives you the power and control to do it right.

Product Video

Applications

- Bearing Installation and Removal: Press bearings in and out of housings with precise, controlled force, preventing damage to expensive components

- Metal Straightening and Forming: Straighten bent shafts, rods, and plates, or form sheet metal into custom shapes for fabrication projects

- Bushing and Seal Installation: Install bushings, seals, and press-fit components with the exact pressure needed for proper seating

- Assembly Operations: Join tight-fitting parts, press gears onto shafts, and assemble mechanical components that require significant force

- Brake and Suspension Work: Remove and install automotive bushings, press out ball joints, and rebuild suspension components

- General Fabrication Tasks: Punch holes, emboss patterns, compress materials, and perform custom metalworking operations with specialized tooling

Key Features & Benefits

- 60 Ton Powerhouse Capacity: You get massive 60 ton pressing force that handles heavy-duty industrial work, yet with the control to work on delicate components without damage

- Intelligent Dual-Speed Operation: Save time with rapid descent for positioning, then automatically switch to slow approach speed for precision work. This smart system speeds up your workflow while maintaining accuracy where it counts

- Triple Control Options: Choose between motorized automatic operation, dual-speed hydraulic mode, or hand pump control. This flexibility means you can match the control method to your specific task for optimal results

- Movable Cylinder Design: The cylinder slides left and right within the frame, allowing you to position pressure exactly where needed. This is invaluable for off-center work and eliminates the frustration of repositioning heavy workpieces

- European Build Quality: Manufactured in the Netherlands using premium components and precise welding techniques. The fully welded 3/8" steel plate construction means this press won't flex under load and will serve your shop for decades

- Height-Adjustable Work Table: The hydraulic-assist table adjustment with lifting chains makes setup easy and protects your back. Lock the table at the perfect height using the two 2" diameter support pins

- Automatic Cylinder Return: After completing your press operation, the chrome-plated piston automatically returns to the top position, speeding up your workflow and reducing operator fatigue

- Industrial Hydraulic System: The precision-engineered hydraulic system with 235 bar maximum pressure delivers smooth, consistent force with minimal noise and vibration, creating a better working environment

What's in the Box

- HSP-66M 60 Ton Hydraulic Press (fully assembled main unit)

- 2-Piece V-Block Set (for supporting round stock and cylindrical components)

- Pressure Gauge (for monitoring and controlling applied force)

- Hand Pump (for manual operation and fine control)

- Lifting Chains (for easy table height adjustment)

- Pressure Regulator

- Ram Cap

- User Manual and Documentation

- Warranty Card

Baileigh HSP-66M Technical Specifications

| Model Number | HSP-66M |

|---|---|

| Maximum Capacity | 60 ton (600 kN) |

| Country of Manufacture | Netherlands |

| Cylinder Stroke | 400 mm (15.75") |

| Working Width | 750 mm (29.5") |

| Motor Power | 1.5 kW (2 hp) |

| Power Requirements | 400V / 3-Phase |

| Cylinder Movable | Yes (left/right adjustment) |

| Overall Dimensions | 1150 x 900 x 2170 mm (45" x 35" x 85") |

| Shipping Weight | 685 kg (1,510 lbs) |

Baileigh HSP-66M Manuals & Downloads

Frequently Asked Questions

What power supply do I need for this press?

The HSP-66M requires 400V three-phase electrical power, which is standard in European industrial facilities. You'll need a dedicated 400V 3-phase circuit with appropriate amperage capacity for the 1.5 kW motor. If you're unsure about your facility's electrical setup, consult with a qualified electrician before ordering.

Can I use this press for both heavy and delicate work?

Absolutely! That's one of the HSP-66M's greatest strengths. The dual-speed hydraulic system automatically switches between rapid descent and slow approach, giving you speed when positioning and precision when pressing. For ultra-delicate work, switch to the hand pump for complete manual control. The pressure gauge lets you monitor exactly how much force you're applying.

How difficult is it to adjust the table height?

Very easy, actually. The table adjustment system includes hydraulic assistance and lifting chains, so you're not manually lifting hundreds of pounds. Simply release the locking pins, use the chains to raise or lower the table to your desired height, then lock it in place with the 2" diameter support pins. The whole process takes just seconds.

What maintenance does this press require?

The HSP-66M is designed for minimal maintenance. You'll need to check the hydraulic oil level periodically and keep it topped up with the recommended hydraulic fluid (30 liter capacity). Inspect the chrome piston for wear, ensure all moving parts remain lubricated, and check hydraulic connections for leaks during routine inspections. The robust European construction means this press is built to run reliably with basic care.

Is the cylinder really movable, and why does that matter?

Yes, the cylinder moves left and right within the H-frame. This is incredibly useful for real-world work. When you need to press an off-center bushing, bearing, or component, you can position the cylinder directly over your work point instead of trying to reposition a heavy workpiece. This saves time, reduces frustration, and ensures you're applying force exactly where needed for better results and safer operation.