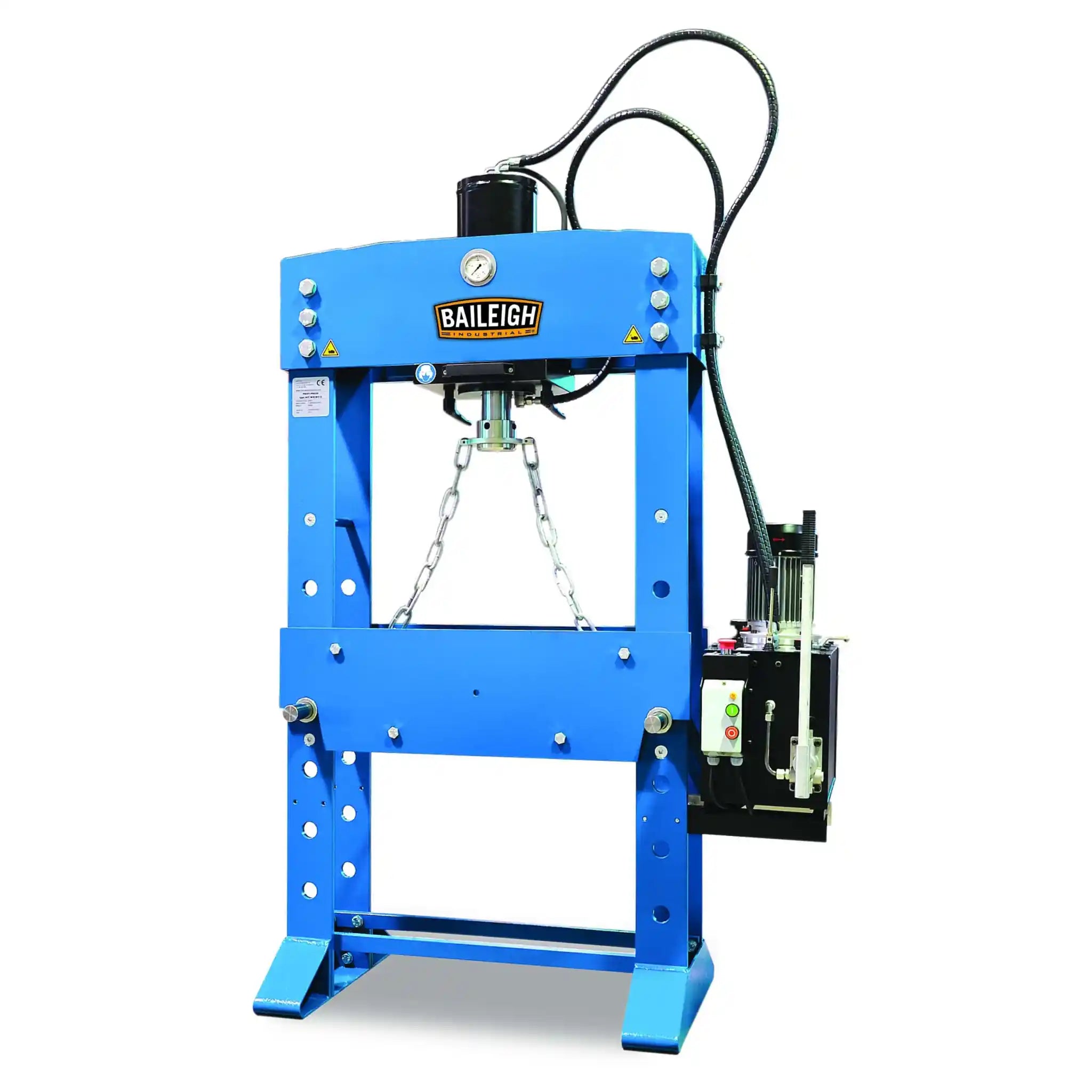

Baileigh HSP-33M Hydraulic Press

The Baileigh HSP-33M is a European built, motorized H-frame hydraulic press delivering 30 metric tons (66,000 lbs) of pressing force, designed for professional fabrication shops, automotive workshops, and industrial maintenance facilities that demand reliability and precision.

Looking for a hydraulic press that can handle the toughest jobs in your workshop? The HSP-33M combines European craftsmanship with intelligent engineering to give you a press that works as hard as you do. Built with a fully welded 3/8" plate steel frame, this press stands up to heavy duty commercial use day after day.

What sets this press apart is its dual-speed electric motor system. You get a rapid descent speed to quickly position your work, then switch to the slow working speed when you need precise control. Can't trust the motor for ultra delicate work? No problem. The included manual hand pump lets you apply pressure incrementally, giving you complete control down to the finest adjustment. This combination of power and precision means you can tackle everything from heavy pressing operations to detailed bearing installations without changing machines.

The 1.5kW three-phase motor drives an industrial grade hydraulic system that's built to last. At 385 kg of solid construction, this isn't a press that will flex or wobble under load. The movable cylinder slides left and right within the frame, letting you position your work exactly where you need it. This is especially valuable when you're working with off center parts or awkwardly shaped components that don't sit perfectly in the middle of the press bed.

Applications

- Bearing Installation and Removal: Press bearings in and out of housings with controlled precision, whether you're working on automotive components, machinery repairs, or equipment maintenance

- Metal Straightening: Correct warped or bent metal components, including plates, bars, shafts, and structural elements that have been damaged or distorted during fabrication or use

- Bushing and Gear Work: Install and remove bushings, gears, pulleys, and other press-fitted components with the exact force needed to avoid damage

- Automotive Repair Tasks: Handle U-joint replacements, ball joint installations, axle bearing work, and other pressing operations common in automotive and truck repair shops

- Metal Forming and Bending: Shape and bend metal components for custom fabrication projects, prototype development, and repair work

- Assembly and Disassembly: Press parts together or separate stubborn assemblies that won't budge with normal tools, saving time and preventing damage

Key Features & Benefits

- Dual-Speed Motor Operation: The rapid descent speed gets you to your work quickly, while the slow working speed gives you the control you need when applying pressure. This saves you time on every job compared to single-speed systems.

- European Build Quality: Manufactured in Europe using premium components and superior craftsmanship, this press is built to withstand decades of professional use in demanding workshop environments.

- Manual Hand Pump Included: When you need ultra-precise control for delicate work, the hand pump lets you apply pressure gradually. This gives you the flexibility to handle both heavy-duty and precision tasks with one machine.

- Movable Hydraulic Cylinder: The cylinder slides horizontally within the frame, allowing you to position it exactly where you need it for off-center work. This feature dramatically expands what you can do with the press.

- Welded Steel Frame Construction: The fully welded 3/8" plate steel H-frame means you can apply the full 30 tons of force without worrying about flexing, bending, or structural failure. This is a press built to handle maximum loads safely.

- Generous Working Capacity: With a 380mm (15") cylinder stroke and 209mm (8.2") cylinder diameter, you have the reach and power to handle substantial workpieces and deep pressing operations.

- Professional-Grade Hydraulics: The industrial hydraulic system operates at 166 bar maximum pressure with a 30-liter oil capacity, ensuring smooth, consistent performance under heavy loads.

- Built to Last: At 395 kg of solid construction, this press is designed for years of constant commercial use. The robust design means fewer repairs and less downtime.

What's in the Box

- Baileigh HSP-33M Hydraulic Press (fully assembled main unit)

- 1.5kW Three-Phase Electric Motor (installed)

- Manual Hand Pump (for precision work)

- Hydraulic Cylinder Assembly (pre-installed and movable)

- Pressure Gauge (for monitoring applied force)

- Adjustable Work Table

- Operator's Manual and Safety Documentation

- Initial hydraulic oil fill (30 liters system capacity, 8 liters working capacity)

Baileigh HSP-33M Specifications

| Model Number | HSP-33M |

|---|---|

| Maximum Pressing Capacity | 30 metric tons (66,000 lbs / 300 kN) |

| Frame Type | Fully Welded H-Frame |

| Frame Material | 3/8" (10mm) Plate Steel |

| Motor Power | 1.5 kW (2 HP) |

| Power Supply | 400V / 3-Phase / 50Hz |

| Cylinder Diameter | 209 mm (8.2") |

| Piston Head Diameter | 100 mm (3.9") |

| Cylinder Stroke | 380 mm (15") |

| Cylinder Position | Movable (left/right adjustment) |

| Machine Weight | 395 kg (871 lbs) |

| Control Options | Electric motor (dual-speed) + Manual hand pump |

Frequently Asked Questions

How much force does this press actually deliver?

The HSP-33M delivers 30 metric tons of force, which equals approximately 66,000 pounds or 300 kilonewtons. This is serious pressing power suitable for professional industrial applications, heavy automotive repair, and metal fabrication work. The force is more than adequate for bearing installation, metal straightening, and assembly work on large components.

Do I need threephase power to operate this press?

Yes, the HSP-33M requires 400V three-phase electrical supply to operate the motor. This is standard in most industrial facilities, professional workshops, and commercial garages. If you don't have three-phase power available, you'll need to have it installed or consider a phase converter. However, you can still use the manual hand pump function without any electrical connection.

Can I use this press for offcenter work?

Absolutely! One of the standout features of the HSP-33M is its movable hydraulic cylinder. The cylinder slides horizontally within the frame, allowing you to position it exactly where you need it for off-center parts or awkwardly shaped workpieces. This dramatically increases the versatility of the press compared to fixed-cylinder designs.

What's the difference between the rapid descent and working speed?

The rapid descent speed (16.7 mm/sec) quickly brings the ram down to your workpiece, saving time on setup. Once you're close to your work, you switch to the working speed (2.2 mm/sec), which moves much slower and gives you precise control as you apply pressure. This two-speed system combines efficiency with precision, making every job faster without sacrificing control.

What kind of maintenance does this press require?

Hydraulic presses are relatively low-maintenance machines. You'll need to check the hydraulic oil level periodically and top it off if needed. Inspect the hydraulic lines and seals for any signs of leaks. Keep moving parts lubricated and the frame clean. Check the pressure gauge regularly to ensure it's functioning correctly. With proper care, this press will provide decades of reliable service in a professional environment.