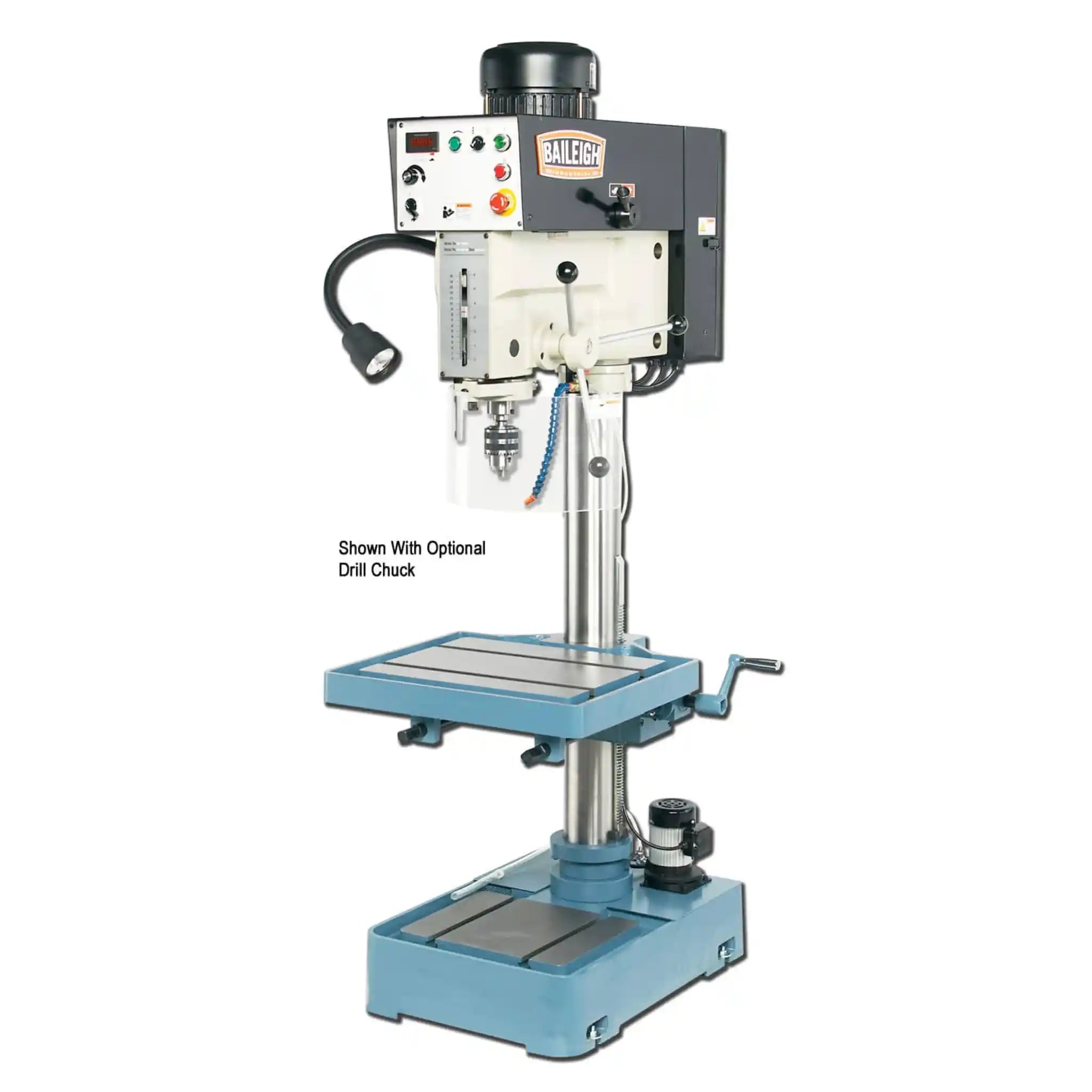

Baileigh DP-1250VS

The Baileigh DP-1250VS is a heavy-duty, floor-standing drill press that combines precision engineering with modern inverter technology, delivering professional-level performance for your metalworking shop. With its 20.8" swing and 32mm drilling capacity in mild steel, this machine gives you the power and accuracy you need to tackle demanding fabrication projects with confidence.

Are you tired of drill presses that flex and wobble when you're working at maximum capacity? The DP-1250VS is built differently. Its oversized column and heavy cast iron construction create a rock-solid foundation that won't budge—even during the most demanding drilling sessions.

What makes this drill press stand out is its intelligent inverter-driven system. Instead of traditional belt-driven speed changes, you get smooth, infinitely variable control from 65 to 2000 RPM through a simple potentiometer dial. The digital readout shows you exactly what speed you're running, so there's no guesswork involved. This means you can dial in the perfect speed for any material, whether you're drilling aluminum, steel, or stainless.

Designed for professional machinists, fabricators, and serious workshop owners, the DP-1250VS handles everything from precision drilling to threading operations. The built-in auto-reversing tap function (up to 19mm capacity) means you can thread holes without switching machines. Plus, the integrated coolant system extends your tool life and improves cut quality—features you'd normally only find on much more expensive machines.

Applications

- Heavy fabrication work: Drilling through thick steel plates, structural components, and heavy-duty brackets where precision matters

- Threading operations: Creating tapped holes up to 19mm with the auto-reverse function—perfect for mounting points and threaded connections

- Repetitive production runs: The digital speed control and rigid construction ensure consistent results across multiple identical parts

- Metalworking projects: From mild steel to stainless steel and aluminum—adjust the speed to match your material for clean, accurate holes

- Jig and fixture drilling: The large T-slotted table and exceptional rigidity make this ideal for precision tooling work

- General machine shop operations: Your go-to drill press for everything from deburring to reaming and countersinking

Key Features & Benefits

- Inverter-Driven Variable Speed Control: Forget about changing belts or settling for limited speed options. You get infinite speed adjustment from 65-2000 RPM with a simple dial, plus a digital display that shows your exact RPM. This means you can optimize cutting speed for any material—resulting in cleaner holes and longer tool life.

- Massive 20.8" Swing Capacity: You're not limited to small parts. This generous swing means you can drill holes in large plates, wide brackets, and oversized workpieces that wouldn't fit on a standard bench drill.

- 32mm (1.25") Drilling Capacity: When you need to drill large holes in mild steel, this machine delivers. The heavy-duty #4 Morse taper spindle transfers power efficiently, even under maximum load.

- Built-In Auto-Reverse Tapping: Why switch to a separate machine for threading? The DP-1250VS taps threads up to 19mm automatically. Just engage the function, and it reverses cleanly after cutting—saving you time and producing perfect threads every time.

- Integrated Coolant System: This isn't just a nice-to-have feature—it's a game-changer for your productivity. The coolant system is stored in the base and sprays directly at the cutting point behind a safety guard. Your drill bits stay cool, cut faster, and last significantly longer.

- Rock-Solid Stability: The wide-diameter column and heavy cast iron base work together to eliminate flex and vibration. When you're drilling at maximum capacity, you'll appreciate how steady this machine stays—it directly translates to more accurate holes and better surface finishes.

- Large T-Slotted Table: The 559mm x 470mm machined table features generous 16mm T-slots, giving you plenty of options for securing vises, fixtures, and workpieces. The table adjusts smoothly for height, and the quality machined surface provides a reliable reference plane.

What's in the Box

- Baileigh DP-1250VS Floor Drill Press (fully assembled base and column)

- Variable speed inverter control panel with digital RPM display

- Cast iron worktable with T-slot configuration

- Spindle guard with integrated safety limit switch

- Operating manual and safety documentation

Baileigh DP-1250VS Specifications

| Motor Power | 1.5 kW (2 HP) |

|---|---|

| Power Supply | 220V / 1-Phase |

| Spindle Speed Range (Low) | 65 – 540 rpm |

Baileigh DP-1250VS Manuals & Downloads

Frequently Asked Questions

Does this drill press come with a chuck, or do I need to purchase it separately?

The DP-1250VS comes with the MT4 spindle taper but does not include a drill chuck or arbor. This design choice lets you select the exact chuck type and capacity that matches your specific needs—whether that's a keyless chuck, keyed chuck, or specialized tooling.

Can I use this drill press for drilling harder materials like stainless steel or cast iron?

Absolutely! The variable speed control is perfect for harder materials. Simply reduce your RPM and use proper cutting fluid (the integrated coolant system helps here). The rigid construction and powerful motor handle stainless steel, cast iron, and other tough materials with appropriate tooling and cutting parameters.

How difficult is the installation and setup?

The DP-1250VS arrives mostly assembled. You'll need to position it in your shop (it weighs 340kg, so plan for proper lifting equipment), level the base, and connect it to 220V single-phase power. Most shops can have it operational within a few hours. The manual provides clear instructions, and Baileigh's lifetime technical support is available if you need guidance.

What maintenance does this drill press require?

Routine maintenance is straightforward: keep the table and column clean, periodically check and top up the coolant system, lubricate the quill and column as recommended in the manual, and verify that all adjustment mechanisms operate smoothly. The inverter drive system requires minimal maintenance compared to traditional belt-driven designs.

Is this suitable for a home workshop, or is it industrialonly?

While the DP-1250VS is built to industrial standards, many serious home workshop owners choose it for its quality and capabilities. The key considerations are: you need 220V single-phase power (common in many home shops), adequate floor space, and the ability to move and position 340kg. If you regularly work with metal and need professional results, this machine is an excellent choice regardless of whether you're running a business or an advanced home shop.