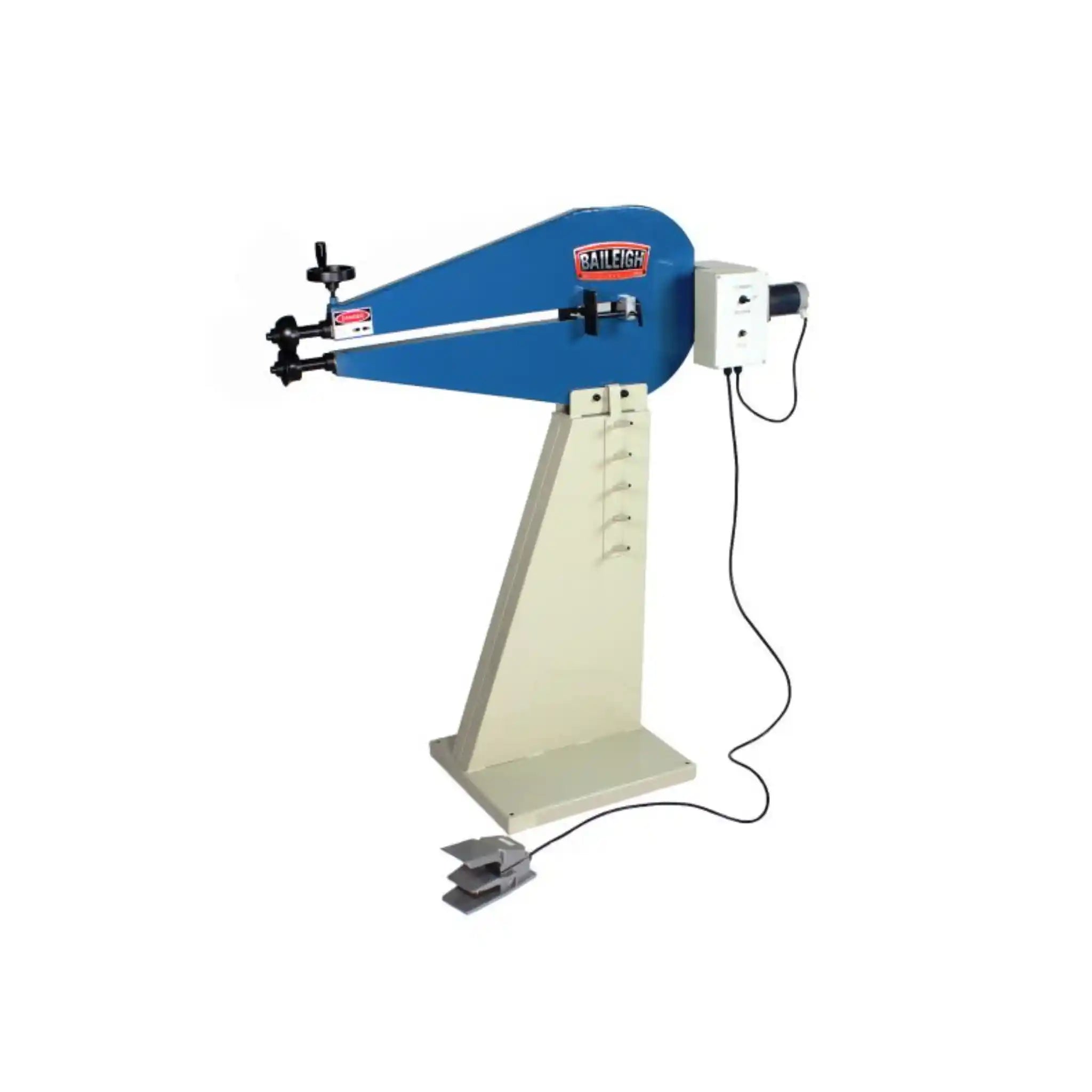

Baileigh BR-18E-24 - 610mm Throat Depth Bead Roller

The Baileigh BR-18E-24 is a professional-grade electric bead roller that puts precision metal forming at your fingertips, featuring a generous 610mm throat depth and variable-speed foot pedal control that keeps your hands free to guide the material exactly where you need it.

Looking to add professional-level strength and styling to your sheet metal projects? The BR-18E-24 power bead roller is your answer. Whether you're fabricating custom automotive panels, creating HVAC ductwork, or producing architectural metalwork, this machine delivers the precision and power you need to create perfect beads, channels, and decorative patterns every single time.

What makes this bead roller special? It's all about giving you control. The variable-speed foot pedal means you can adjust your rolling speed on the fly - press harder for faster feed rates, ease up for delicate work. Your hands stay free to guide the metal, making intricate patterns and complex shapes surprisingly manageable. The 610mm throat depth is the sweet spot for versatility - deep enough to reach the centre of standard 2m x 2.5m sheet metal panels, yet compact enough for detailed pattern work.

Built on a fully-welded plate steel frame with an industrial-grade motor and gearbox, this machine is designed for fabrication shops, automotive restoration businesses, and serious metalworkers who need equipment that can handle daily production. The bronze bushings on all moving parts mean you'll get years of consistent performance with minimal maintenance.

Applications

- Automotive Restoration & Custom Fabrication: Create hoods, deck lids, roof panels, floor pans, firewalls, and custom body panels with professional-quality beads and styling lines

- Structural Reinforcement: Add strength and rigidity to sheet metal panels by creating beads that prevent warping and distortion in large flat surfaces

- Ductwork Manufacturing: Form channels, flanges, and connection points in ductwork and ventilation components

- Architectural Metalwork: Produce decorative patterns, raised beads, and custom profiles for interior and exterior metal features

- Industrial Panel Fabrication: Manufacture equipment panels, enclosures, and protective covers with integrated strengthening beads

- Aircraft Components: Form precise beads in aluminum panels for aircraft repair and custom aviation applications

Key Features & Benefits

- Hands-Free Operation with Variable Speed Control: The foot pedal gives you complete control over rolling speed while keeping both hands free to position and guide your material - perfect for intricate patterns and tight curves

- Professional 610mm Throat Depth: Reach the middle of large panels (up to 2m x 2.5m sheets) with ease, yet maintain the precision needed for detailed decorative work and small components

- Powerful 1/8 HP Industrial Motor: Handles 1.25mm mild steel and 1.6mm aluminum capacity with consistent power - the motor won't bog down even on demanding production runs

- Forward and Reverse Rolling: Simply flip the switch to change direction, making it easy to work around complex shapes and reach tricky areas without repositioning your entire workpiece

- Precision Adjustable Depth Control: Set your exact bead depth with the adjustable top roll and lead screw - the included depth stop ensures perfectly straight, repeatable beads every single time

- Built for Longevity: All moving parts run on bronze bushings with grease fittings for easy maintenance, while the fully-welded plate steel frame eliminates flex and maintains precision over years of heavy use

- Universal Tooling Compatibility: The 3/4" (19mm) shaft diameter accepts most commercially available roll sets, giving you access to hundreds of profile options for different applications

- Complete Setup Ready to Work: Arrives with heavy-duty floor stand, integrated die rack for organizing your roll sets, roll holder, and adjustable depth stop - you're ready to start forming metal right out of the crate

What's in the Box

- BR-18E-24 Power Bead Roller Machine

- Heavy-Duty Floor Stand (fully assembled)

- Variable Speed Foot Pedal Controller

- Adjustable Depth Stop Assembly

- Roll Holder

- Integrated Die Rack (stores your bead roller dies)

- Hardware Kit (all mounting hardware and fasteners)

- Owner's Manual with setup and operation instructions

Baileigh BR-18E-24 Specifications

| Model Number | BR-18E-24 |

|---|---|

| Throat Depth | 610mm (24") |

| Material Capacity - Mild Steel | 1.25mm (16 gauge) |

| Material Capacity - Aluminum | 1.6mm (14 gauge) |

| Motor Power | 1/8 HP (0.093 kW) |

| Power Supply | 220V, 50Hz, 1 Phase |

Baileigh BR-18E-24 Manuals & Downloads

Frequently Asked Questions

What roll sets/dies are compatible with this bead roller?

The BR-18E-24 uses a standard 3/4" (19mm) shaft diameter, making it compatible with most commercially available roll sets including Baileigh, Mittler Brothers, and other major brands. You can use flat bead dies, round bead dies, step dies, tipping dies, flange dies, and specialty profiles. Baileigh offers over 300 different die profiles for various applications.

How difficult is it to change between different roll sets?

Very straightforward! The design allows for quick roll changes so you can switch between different profiles efficiently. The integrated die rack on the stand keeps your roll sets organized and within easy reach.

Do I need special electrical installation for the 220V model?

The BR-18E-24 EU version operates on standard 220V, 50Hz, single-phase power. Most European workshops and facilities already have this power available. Always ensure your electrical supply matches the machine's requirements and consult a qualified electrician if needed.

Can this machine handle stainless steel?

The BR-18E-24 is rated for 1.25mm mild steel and 1.6mm aluminum. While it can handle lighter gauge stainless steel (typically 18-20 gauge or thinner), you'll need to reduce the material thickness from the mild steel rating. For regular heavy-gauge stainless steel work, you might want to consider a heavier-duty model.

How much maintenance does this bead roller require?

Minimal maintenance is required. Regularly lubricate the bronze bushings through the grease fittings (every 40-50 hours of operation or monthly), keep the machine clean from metal debris, and periodically check that all bolts remain tight. The simple, robust design means there's very little that can go wrong with proper care.